Lab Fabricated Diamonds: My Journey from Skeptic to Believer

Lab Fabricated Diamonds: My Journey from Skeptic to Believer

Last summer, my best friend Jake called me up with news that stopped me cold. He was getting engaged, and he wanted my opinion on something that sounded completely nuts to me at the time. "I'm thinking about getting a manufactured diamond," he said. "You know, one of those lab-made ones."

My first reaction? "Dude, that's basically a fake diamond. Why would you do that to yourself?"

Fast forward eight months, and I'm sitting here writing about why Jake was absolutely right and I was completely wrong. The story of how I went from thinking lab fabricated diamonds were glorified costume jewelry to understanding they're actually superior to natural diamonds in almost every way is... well, it's embarrassing how wrong I was, but also pretty fascinating.

See, Jake didn't just randomly decide to go with a manufactured diamond. His girlfriend Ashley had done months of research after watching a documentary about diamond mining. She wasn't being cheap or trying to save money – she genuinely preferred the idea of a diamond that was created intentionally rather than dug out of the ground. Jake, being a smart guy, listened to her reasoning and started doing his own research.

When he tried to explain it to me, I wasn't having it. "But it's not real," I kept saying. "It doesn't have the same history, the same meaning." Looking back, I realize I was basically arguing that something formed randomly in the earth over millions of years was somehow more meaningful than something created intentionally using human knowledge and technology. When you put it that way, my position sounds pretty ridiculous.

The turning point came when Jake invited me to go ring shopping with him. We went to three different jewelry stores, and at each one, I asked to see both natural and manufactured diamonds side by side. I was convinced I'd be able to tell the difference immediately and prove my point about "real" versus "fake" diamonds.

I couldn't tell the difference. Not even close.

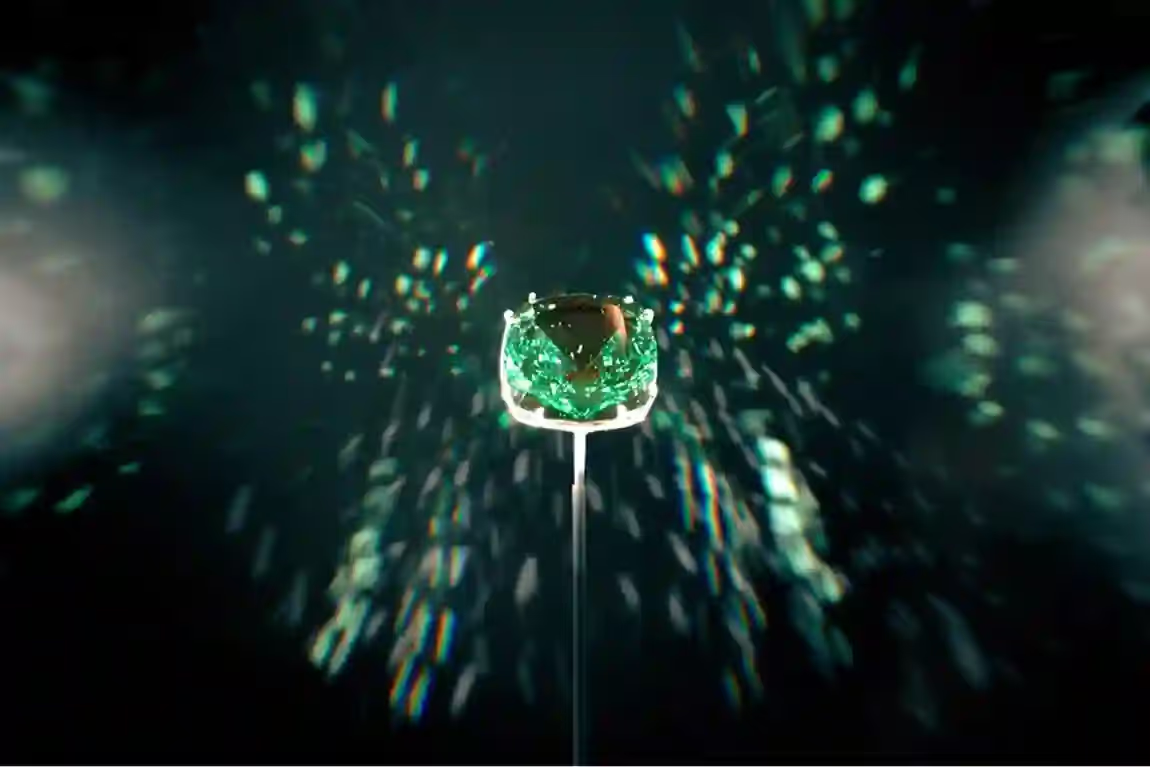

In fact, the cultured diamonds often looked better than the natural ones – clearer, more brilliant, fewer visible flaws. When I asked the jewelers to explain what I was seeing, they were refreshingly honest about it. "The lab-made stones are usually higher quality because they're grown in controlled conditions," one explained. "Nature is messy. Laboratories are precise."

That conversation started me down a rabbit hole that lasted months and completely changed how I think about diamonds, technology, and what makes something "real" or valuable.

The Science That Blew My Mind

I'm not a scientist, but I had to understand how you actually make a diamond in a lab. Turns out, it's not magic – it's just really advanced chemistry and physics.

There are basically two ways to fabricate diamonds, and both involve recreating the extreme conditions that exist deep in the Earth where natural diamonds form. The difference is that instead of waiting millions of years and hoping for the best, scientists can control every aspect of the process.

The first method is called HPHT – High Pressure High Temperature. Imagine taking a tiny piece of diamond (called a seed) and subjecting it to pressures that would crush a car and temperatures hot enough to melt copper. In these conditions, carbon atoms from surrounding materials start attaching to the seed, building up layer by layer to create a larger diamond crystal.

The second method, CVD or Chemical Vapor Deposition, sounds even more like science fiction. Scientists put a diamond seed in a chamber filled with methane gas, then use microwaves to break apart the gas molecules. The freed carbon atoms float down and attach to the seed, slowly building up a diamond crystal atom by atom.

Both processes take weeks rather than millions of years, and the level of control is incredible. Scientists can influence the color, clarity, size, and even the shape of the diamonds as they grow. It's like having a 3D printer for diamonds, except the "ink" is pure carbon and the result is harder than anything else on Earth.

When I visited a diamond fabrication facility outside Las Vegas (yeah, that became a thing I did), watching this process in action was absolutely mind-blowing. Seeing actual diamonds crystallizing in real time, knowing that every atom was being placed exactly where it needed to be, felt like witnessing the future.

The technical precision is what really got to me. Natural diamond formation is basically geological chaos – random pressure, random heat, random impurities. Lab fabrication is the opposite – controlled pressure, controlled heat, controlled environment. Which approach do you think produces better results?

Why I Was Wrong About "Real" Diamonds

My biggest hangup was this idea that manufactured diamonds weren't "real" diamonds. Turns out, this is scientifically nonsense.

A diamond is defined by its chemical composition (pure carbon) and crystal structure (carbon atoms arranged in a specific lattice pattern). Lab fabricated diamonds have exactly the same composition and structure as natural diamonds. Same hardness rating (10 on the Mohs scale), same optical properties (how they bend and reflect light), same thermal conductivity (how they handle heat).

If you took a natural diamond and a cultured diamond of similar quality and put them side by side, even experienced gemologists can't tell them apart without specialized testing equipment. The machines they use don't detect "naturalness" – they detect tiny trace elements and growth patterns that indicate where and how the diamond formed.

But here's the kicker: manufactured diamonds often have fewer impurities and more consistent quality than natural ones. When nature makes diamonds, it's working with whatever carbon and conditions happen to be available 100+ miles underground. When labs make diamonds, they're working with pure materials in precisely controlled environments.

The result? Cultured diamonds frequently have better color grades, higher clarity ratings, and more consistent quality than natural diamonds. If you're judging purely on the characteristics that make diamonds beautiful – brilliance, fire, scintillation – manufactured diamonds often win.

This completely flipped my understanding of what makes something "better." I was valuing randomness over precision, geological accident over intentional creation. Once I realized that, my whole perspective changed.

The Economics That Changed Everything

Let's talk money, because this is where things get really interesting.

Jake's engagement ring ended up costing about $4,500 for a stunning 1.5-carat manufactured diamond with excellent cut, color, and clarity. A comparable natural diamond would have run somewhere between $12,000 and $18,000. That's not a small difference – that's life-changing money for most people.

But Jake didn't choose the lab fabricated diamond just to save money. He chose it because for the same budget, he could get a much larger, higher-quality stone than what natural diamonds would have offered. Ashley's ring is absolutely gorgeous – the kind of piece that stops conversations when she walks into a room.

The price difference comes down to basic supply chain economics. Natural diamonds have to be found (which is getting harder as easy deposits are exhausted), mined (expensive and environmentally destructive), sorted (most diamonds aren't gem quality), and distributed through a supply chain that's been controlled by a handful of companies for decades.

Manufactured diamonds sidestep all of that. They can be produced anywhere there's electricity and the right equipment. No mining, no geographic limitations, no artificial scarcity. The main costs are energy and equipment, both of which are becoming cheaper and more efficient over time.

This trend is accelerating. Cultured diamonds that cost $3,000 five years ago might cost $1,500 today. Meanwhile, high-quality natural diamonds are becoming more expensive as the easiest sources are depleted. The economic advantage of manufactured diamonds is growing, not shrinking.

For consumers, this opens up possibilities that didn't exist before. Want matching earrings with large, high-quality diamonds? Easy with manufactured stones, prohibitively expensive with natural ones. Want a specific color that's extremely rare in nature? Labs can create that. Want the biggest, most brilliant diamond possible for your budget? Cultured diamonds win every time.

The Environmental Reality Check

This wasn't something I initially cared much about, but the environmental comparison between natural and manufactured diamonds is pretty stark.

Diamond mining involves moving massive amounts of earth – sometimes 200+ tons of rock and soil to find a single carat of gem-quality diamonds. The Mir mine in Russia is so big you can see it from space. The environmental impact includes destroyed ecosystems, polluted water sources, enormous energy consumption for mining equipment, and massive waste piles that don't return to their original state.

Lab fabricated diamonds need energy too – those diamond-growing machines aren't exactly energy efficient. But even accounting for electricity usage, the environmental footprint is a small fraction of what mining requires. No massive holes in the ground, no ecosystem destruction, no moving mountains of dirt to find tiny gems.

Many diamond fabrication facilities are now powered by renewable energy sources, making their environmental impact even smaller. Some companies are specifically marketing "solar-powered diamonds" or "wind-powered diamonds," which sounds pretty cool when you think about it.

The water usage comparison is dramatic too. Diamond mining uses enormous amounts of water for processing and dust control. Diamond fabrication uses relatively little water, and what's used can often be recycled within the facility.

I'm not a hardcore environmentalist, but when you can get a better product that causes dramatically less environmental damage for less money, it seems like an obvious choice.

What Jewelers Actually Tell You

One thing that surprised me during this whole journey was how honest most jewelers were about manufactured diamonds once you got past the initial sales pitch.

The older generation of jewelers definitely has mixed feelings. They've spent decades building businesses around natural diamond scarcity and the romantic story of stones formed millions of years ago. Cultured diamonds challenge both the business model and the narrative they've been selling.

But even traditional jewelers acknowledge the quality advantages of manufactured diamonds. One jeweler in his sixties told me, "I can't argue with the science. These lab-made stones are often clearer and more brilliant than natural ones. If I'm being honest with customers about quality, I have to mention that."

Younger jewelers tend to be more enthusiastic about cultured diamonds. They see them as offering better value and opening up design possibilities that weren't economically feasible with natural stones. "I can design pieces around large, high-quality diamonds without worrying about whether customers can afford them," one designer told me.

The generational divide among customers is even more pronounced. Millennials and Gen Z buyers often prefer manufactured diamonds because they align with values around sustainability, technology, and getting good value for money. Older buyers are more likely to stick with natural diamonds for traditional reasons.

What's interesting is how many jewelers now carry both options and let customers decide based on their priorities. The smart ones present the facts honestly and help customers choose what works best for their situation rather than pushing one option over the other.

Shopping for Cultured Diamonds

When I finally decided to buy some lab fabricated diamonds myself (spoiler alert: I got my wife anniversary earrings), the shopping process taught me a lot about how this market actually works.

First lesson: not all manufactured diamonds are created equal. Different growing methods produce different results, and some facilities have better quality control than others. Just like natural diamonds, you need to pay attention to grading and certification.

The two main growing methods – HPHT and CVD – each have advantages. HPHT diamonds tend to have excellent clarity but sometimes slight color tints. CVD diamonds usually have better color consistency but might have different inclusion patterns. For most consumers, these differences are subtle enough that other factors (price, availability, specific grading) matter more.

Certification matters just as much for cultured diamonds as natural ones. The major grading institutes (GIA, IGI, etc.) use the same standards for manufactured diamonds, so you get the same detailed analysis of cut, color, clarity, and carat weight.

Shopping online versus in-person has trade-offs. Online retailers often have better prices and larger selections, but you can't see the actual stones before buying. Physical stores let you compare diamonds side by side but typically have higher prices and smaller selections of manufactured diamonds.

The sweet spot for me was finding a jeweler who specializes in cultured diamonds and has both online and physical locations. I could browse their full selection online, then visit their showroom to see my top choices in person before making a final decision.

One advantage of shopping for manufactured diamonds: you can be much pickier about quality for the same budget. With natural diamonds, you often have to compromise on something – size, color, clarity, or price. With cultured diamonds, you can afford to hold out for exactly what you want.

The Emotional Journey

Here's something I didn't expect: buying manufactured diamonds actually felt more personal and meaningful than I thought it would.

With natural diamonds, you're essentially buying whatever geological lottery ticket happened to win millions of years ago. The specific characteristics of your stone were determined by random conditions that existed before humans even evolved.

With cultured diamonds, someone specifically created that stone using current human knowledge and technology. Every atom was placed intentionally. The clarity, color, and size were chosen rather than discovered. There's something deeply personal about that level of intentionality.

When I look at my wife's earrings, I think about the scientists who figured out how to recreate conditions that exist 100 miles underground. I think about the precision required to grow perfect crystals atom by atom. I think about decades of research that made it possible to create diamonds more perfect than anything nature produces randomly.

That feels romantic to me in a way that's different from but not less than the "millions of years old" story. It's the romance of human achievement and ingenuity rather than geological accident.

My wife had a similar reaction. She loves that her diamonds represent the pinnacle of current technology and human understanding. The fact that we could choose exactly the characteristics we wanted feels more personal than being limited to whatever nature happened to provide.

Common Objections (And Why They're Wrong)

During my journey from skeptic to advocate, I heard every possible objection to manufactured diamonds. Most of them don't hold up to scrutiny.

"They don't hold their value" Neither do natural diamonds, if we're being honest. Try selling a diamond ring back to a jewelry store and see what they offer you. Diamonds aren't good investments regardless of where they came from. You buy them because they're beautiful and meaningful, not because you expect them to appreciate in value.

"People can tell the difference" No, they can't. Not visually, and not without specialized equipment. I've tested this extensively with friends and family. Even people who claim they can tell the difference fail blind tests consistently.

"They're not unique" Every cultured diamond is still individually grown and develops its own characteristics during formation. While labs can control general parameters, each stone is unique in its specific inclusion patterns and subtle variations.

"The technology is too new" Diamond synthesis has been around for over 50 years, with gem-quality production capability for more than a decade. The technology is mature and reliable, with consistent quality improvements over time.

"It's not romantic" Romance is subjective, but I find the story of human ingenuity and technological achievement pretty romantic. Creating perfect diamonds using current knowledge feels more intentional and meaningful than relying on geological accidents.

"They'll flood the market and become worthless" Maybe, but that would also make beautiful diamonds accessible to everyone instead of being luxury items for the wealthy. Sounds like a good thing to me.

The Technology Keeps Getting Better

The advancement in diamond fabrication technology over just the past few years has been remarkable. What seemed impossible when I started this journey is now routine.

Size capabilities have expanded dramatically. Early manufactured diamonds were typically limited to smaller stones, but facilities can now produce high-quality diamonds of 5+ carats routinely. I've seen lab-created diamonds exceeding 10 carats that are absolutely spectacular.

Color control has improved to the point where labs can create fancy colored diamonds in shades that are extremely rare or impossible in nature. Want a perfectly saturated blue diamond? Or pure red? Or colors that don't even have names? Modern fabrication techniques can do that.

Growing speed continues to increase. What once took months can now be accomplished in weeks, and researchers are working on techniques that could reduce growing times even further. Faster production means lower costs and the ability to create custom stones more quickly.

Quality consistency keeps improving as facilities refine their processes and equipment. The variation between diamonds from the same facility is often smaller than the variation you'd find in natural diamonds from the same mine.

Perhaps most exciting is research into creating diamonds with properties that don't exist in nature. Scientists are exploring ways to incorporate specific optical characteristics, unique fluorescence patterns, or even microscopic identifying features directly into the crystal structure.

Industry Disruption in Real Time

Watching the diamond industry adapt to manufactured diamonds has been fascinating. Traditional players are responding in different ways, from embrace to denial to attempted market segmentation.

Some established diamond companies have launched their own cultured diamond divisions, recognizing that fighting the technology isn't as profitable as participating in it. Others are doubling down on marketing natural diamonds as luxury products for customers who specifically value rarity and natural origin.

New companies focused exclusively on manufactured diamonds are challenging traditional retail models with direct-to-consumer sales, transparent pricing, and technology-focused marketing. They're particularly successful with younger customers who prioritize value and sustainability.

The supply chain is being completely reimagined. Instead of mines in remote locations, sorting facilities, and complex distribution networks, manufactured diamonds can be produced near major population centers and sold directly to consumers or through streamlined retail channels.

Pricing pressure on natural diamonds is real and increasing. As more consumers discover they can get better quality manufactured diamonds for less money, natural diamond sellers are forced to compete on value rather than relying solely on tradition and marketing.

The most interesting development might be the emergence of hybrid business models – companies that offer both natural and manufactured diamonds and help customers choose based on their specific preferences and priorities rather than pushing one option over the other.

What This Means for Consumers

The growth of cultured diamonds represents one of the biggest shifts in the jewelry industry in decades, and the implications for consumers are almost entirely positive.

More options means better outcomes for everyone. Whether you choose natural or manufactured diamonds, you now have alternatives that didn't exist before. Competition benefits consumers regardless of which option they ultimately select.

Better value is obvious with manufactured diamonds, but even natural diamond pricing has become more competitive in response to cultured alternatives. The entire market is becoming more consumer-friendly.

Higher quality is available at every price point. What used to require a massive budget to achieve in natural diamonds is now accessible to middle-class consumers through manufactured alternatives.

Transparency has increased across the industry. The growth of cultured diamonds has forced more honest conversations about all diamonds – their origins, characteristics, pricing, and value propositions.

Innovation in design and jewelry concepts is accelerating as larger, higher-quality diamonds become economically feasible for more applications. Jewelry designers can be more creative when they're not constrained by the cost and availability limitations of natural diamonds.

Personal Recommendations Based on Experience

After going through this entire journey myself, here's what I tell friends who ask about manufactured diamonds:

If you can afford natural diamonds and the origin story genuinely matters to you, go for it. There's nothing wrong with valuing tradition, rarity, and geological history. Just make sure you're choosing based on your actual preferences rather than outdated assumptions about quality or value.

If you want the best possible diamond for your money, or if you care about environmental impact, or if you appreciate technology and precision, cultured diamonds are probably the better choice. You'll get more size, better quality, and significant cost savings.

Don't let other people's opinions override your own judgment. Some people will have strong feelings about your choice either way. Make your decision based on what matters to you, not what others might think.

Consider starting with smaller pieces to get comfortable with manufactured diamonds before making major purchases. I bought my wife's earrings before we were ready to upgrade her engagement ring, and that experience gave us confidence in the quality and our choice.

Shop around extensively. The manufactured diamond market is competitive and evolving rapidly. Prices and quality can vary significantly between retailers and manufacturers.

Focus on the same quality factors that matter for natural diamonds – cut, color, clarity, and carat weight. The growing method matters less than the final result.

Get proper certification from recognized grading institutes. Manufactured diamonds should be graded using the same standards as natural ones.

Don't overthink the technology details. Both HPHT and CVD methods can produce excellent diamonds. Choose based on the specific characteristics of individual stones rather than the growing method used.

The Bigger Picture

My journey from manufactured diamond skeptic to advocate taught me something bigger than just diamond shopping. It's a reminder of how quickly technology can disrupt established industries and challenge assumptions we didn't even realize we had.

The diamond industry seemed timeless and unchangeable. Natural diamonds had been the only option for centuries, and the marketing around them was so effective that many people (including me) never questioned whether there might be better alternatives.

But technology doesn't care about tradition or marketing. When scientists figured out how to create diamonds that are chemically and physically superior to natural ones at a fraction of the cost, they fundamentally changed what's possible.

This pattern is happening across industries. Technologies that seemed impossible a decade ago are now routine. Products that seemed permanent and unchangeable are being disrupted by better alternatives.

The smart approach is staying open to new information and being willing to change your mind when the evidence warrants it. My preconceptions about manufactured diamonds were based on outdated information and emotional attachments to traditional approaches rather than current reality.

Jake was right to trust his girlfriend's research and his own judgment over conventional wisdom and social expectations. Their choice led to a better outcome – a more beautiful ring at a lower cost with less environmental impact.

Looking Forward

The manufactured diamond industry is still in its early stages, and the developments I've seen just in the past year suggest we're heading toward even more dramatic changes.

Production costs continue falling as technology improves and scales up. Cultured diamonds that seem expensive today will probably look overpriced in a few years.

Quality keeps improving as facilities refine their processes. The gap between average manufactured diamonds and average natural diamonds is widening in favor of the manufactured ones.

New applications beyond jewelry are emerging as high-quality diamonds become more affordable. Industrial uses, electronics, and even quantum computing applications could drive much larger markets than jewelry ever did.

Consumer acceptance is accelerating, particularly among younger buyers who don't have emotional attachments to traditional diamond marketing. This trend seems likely to continue as more people discover the advantages of manufactured diamonds.

The natural diamond industry will adapt by focusing on customers who specifically value rarity and natural origin, but their market share will probably continue shrinking as manufactured alternatives improve and become more widely accepted.

Five years from now, I expect manufactured diamonds will be the default choice for most consumers, with natural diamonds occupying a luxury niche market similar to how mechanical watches coexist with digital ones.

Whatever happens, consumers win. More options, better quality, lower prices, and increased transparency benefit everyone regardless of which type of diamonds they ultimately choose.

Final Thoughts

Writing this has been a strange experience because it's forced me to confront how wrong I was about something I felt confident about. My initial reaction to Jake's manufactured diamond plan was based on assumptions I'd never questioned and information I'd never verified.

The process of actually researching cultured diamonds, visiting facilities, talking to experts, and examining stones myself completely changed my perspective. What I discovered was that manufactured diamonds aren't just equivalent to natural ones – they're often superior in every measurable way except rarity.

That doesn't automatically make them "better" for everyone. Some people genuinely value the natural origin story and are willing to pay significantly more for it. That's a valid preference, and there's nothing wrong with making that choice.

But for people who care primarily about getting beautiful, high-quality diamonds that represent good value for money, manufactured diamonds are hard to beat. The technology has reached the point where the only compromises are psychological rather than practical.

My wife loves her anniversary earrings, I love what we got for our money, and I love the story of human achievement they represent. Six months later, I have zero regrets about choosing manufactured diamonds.

More importantly, this whole experience reminded me of the importance of questioning assumptions and staying open to new information. The world changes fast, and yesterday's impossibilities become today's routine options.

Jake's engagement to Ashley is going great, by the way. Their wedding is next month, and that lab fabricated diamond ring still stops conversations wherever they go. None of their friends or family can tell it wasn't mined from the ground, and most of them are impressed by the size and quality when Jake explains their choice.

That's probably the best endorsement I can give for manufactured diamonds – they deliver everything you want from a diamond without the compromises you might expect. In a world where technology keeps making impossible things possible, that feels like exactly the kind of progress worth celebrating.